High quality precision

components

Metal chipping: since 1968.

Contract Manufacturing

Machining of single items and series

As a contract manufacturer and expert in the machining of complex workpieces, we specialize in the production of precision parts for our clients, including, for example, the automotive and mechanical industries, as well as the plant engineering and packaging sectors.

Other than providing the geometric design for the workpieces, we efficiently integrate any required external production steps into our workflow: heat treatment, Teflon coating, and deep hole drilling are just a few examples.

This way, the workpieces can be delivered ready for assembly and, if required, fully mounted - on time and with tested quality.

|  |

|---|---|

|  |

|  |

|  |

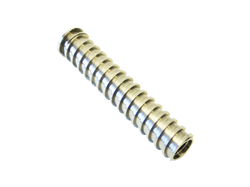

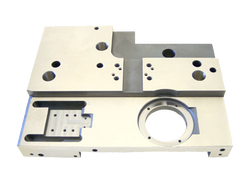

Exemplary selection of sophisticated single components

Testing Gauges

Mechanical measuring and testing systems

Instead of relying on complex and cost-intensive technology, we use traditional, precise, and reliable solutions on a mechanical basis - based on the customer's specifications or on customized design.

The measuring and testing devices are manufactured in our own machine park with high vertical integration. Examples include insertion gauges, checking gauges or measuring devices for workpiece inspection during production (e.g. wheel carriers in the automotive industry).

In our construction department we develop and design solutions in the field of machining and measuring technology. The technical documentation is done according to customer specification.

Furthermore, CAM programming and prototyping technologies such as 3D printing enable us to flexibly respond to the most diverse requirements.

CAD/CAM

In-house design

Family-owned - for over 50 years

in 3rd generation

From cutting machine operators to master craftsmen, technicians, and engineers:

Drawing on decades of experience, the use of modern technologies, and efficiently planned processes, we operate with the highest standards of knowledge that we apply to each and every task.

The greatest capital is our employees, who implement this claim with great commitment and continuously strive to satisfy our customers.

Our machinery and equipment

Our extensive machinery and equipment enable us to process the majority of orders entirely in-house, which is key to our excellent level of quality.

A current list of our machinery is available for download.

For inquiries please use our contact form.

Contact & Manufacturing Inquiries

K.-H. Kuhn GmbH

Werkzeug-

Vorrichtungs-

und Lehrenbau

Gustav-Werner Street 8

72636 Frickenhausen

Germany

CEOs:

Karl-Heinz Kuhn and

Jürgen Kuhn